UV Sterilization Machine Simulation

This project focused on simulating and optimizing an autonomous UV sterilization machine to achieve a log 3 reduction of RNA viruses. The project was a collaborative team effort sponsored by Jeffrey Levitt, CEO and Founder of Applied UVc, a San Diego-based startup. This effort was carried out by a team of talented engineers from the University of California San Diego as a Senior Design Capstone project.

My Contributions

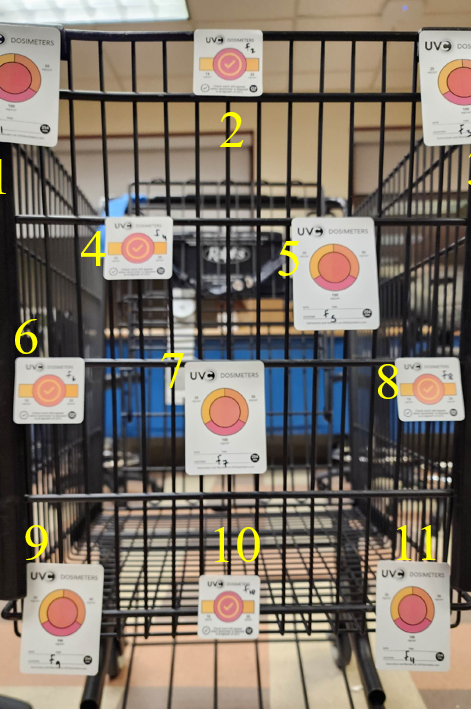

My main contributions to this project were the optimization and simulation of UV light distribution and the development of image processing software. The simulation work aimed to achieve effective UV dosage around critical areas such as high contact surfaces: handles, and seating areas. The image processing software was used to analyze and validate experimental test results, ensuring the accuracy and effectiveness of the UV sterilization process. My role involved working closely with team members to test UV dosages across 100+ trials, validating sanitation efficiency through thorough image processing and analysis of experimental results.

Ultra Violet Ray Simulation

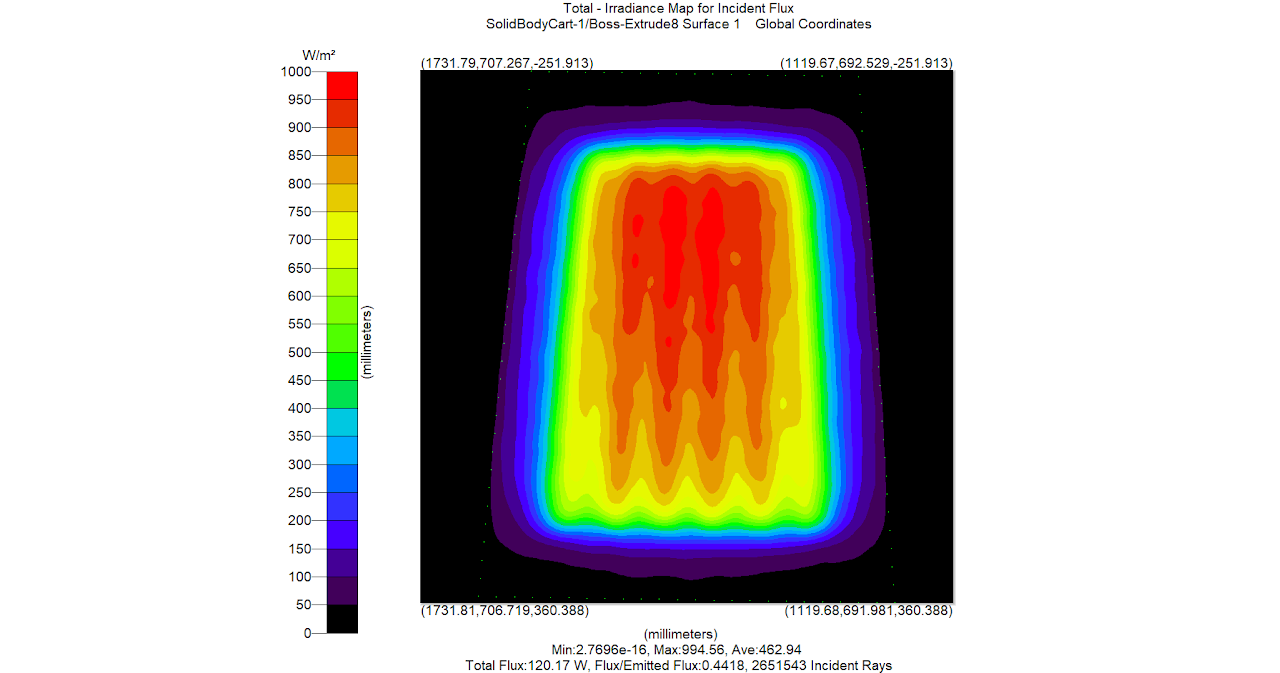

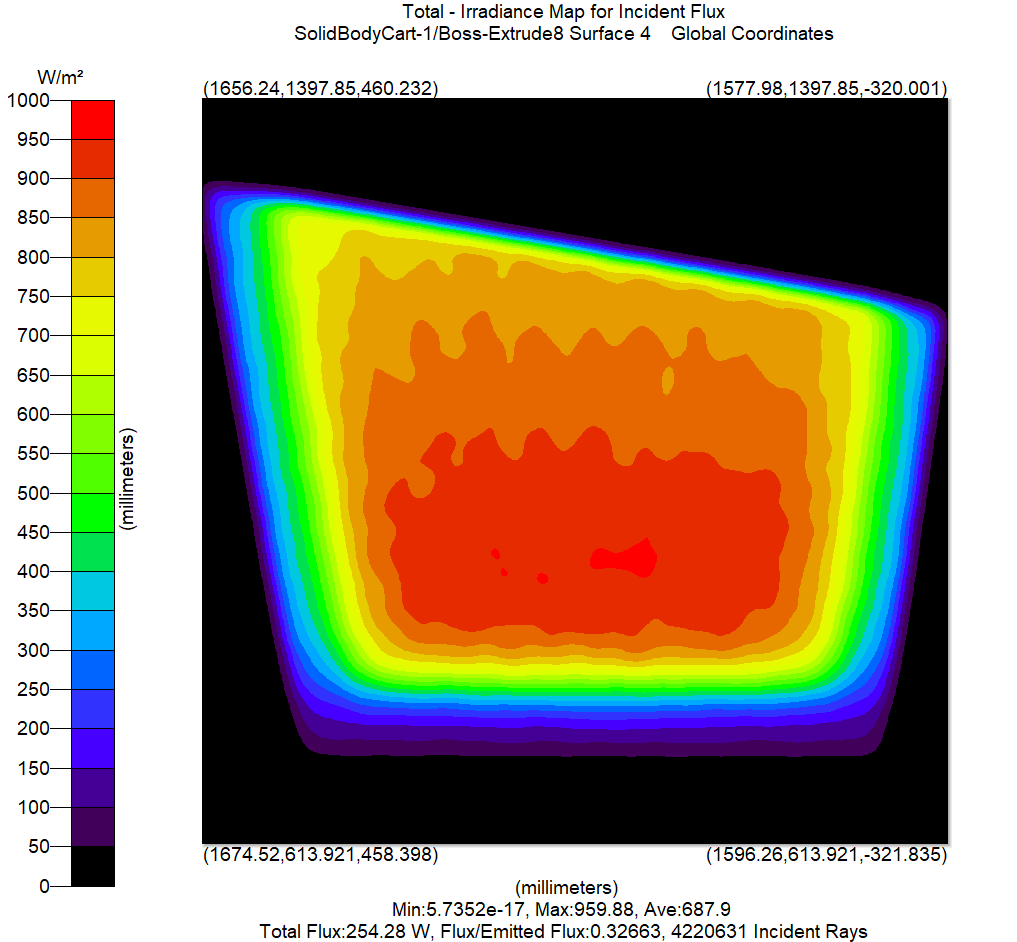

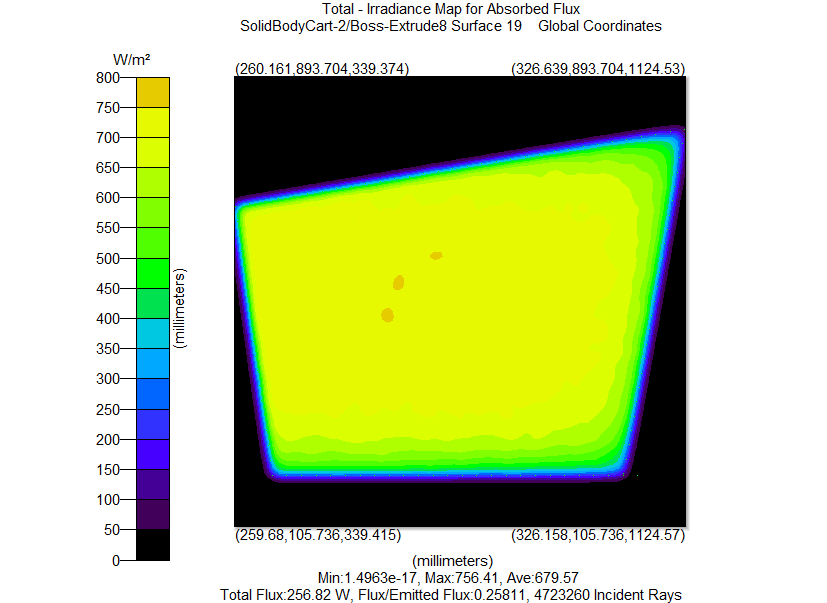

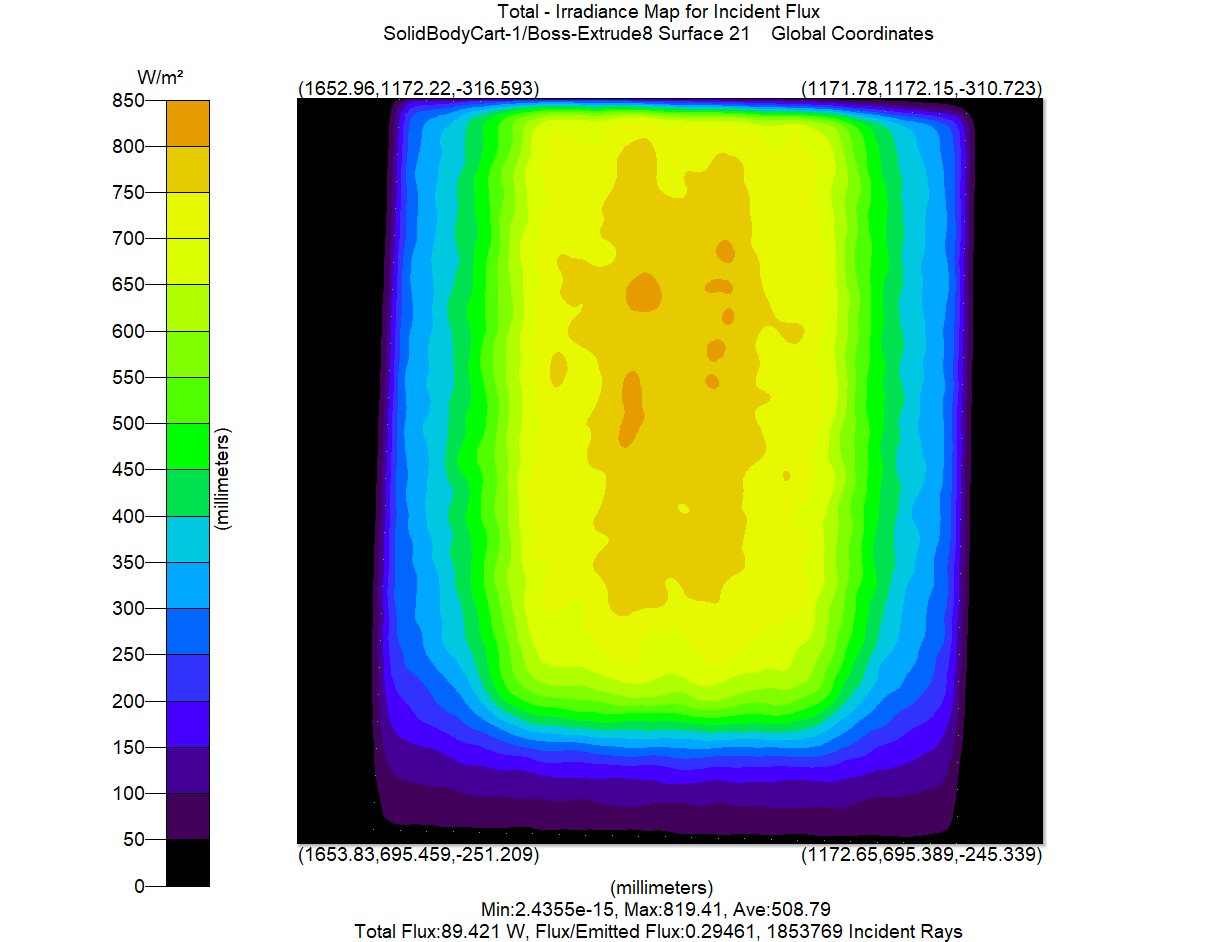

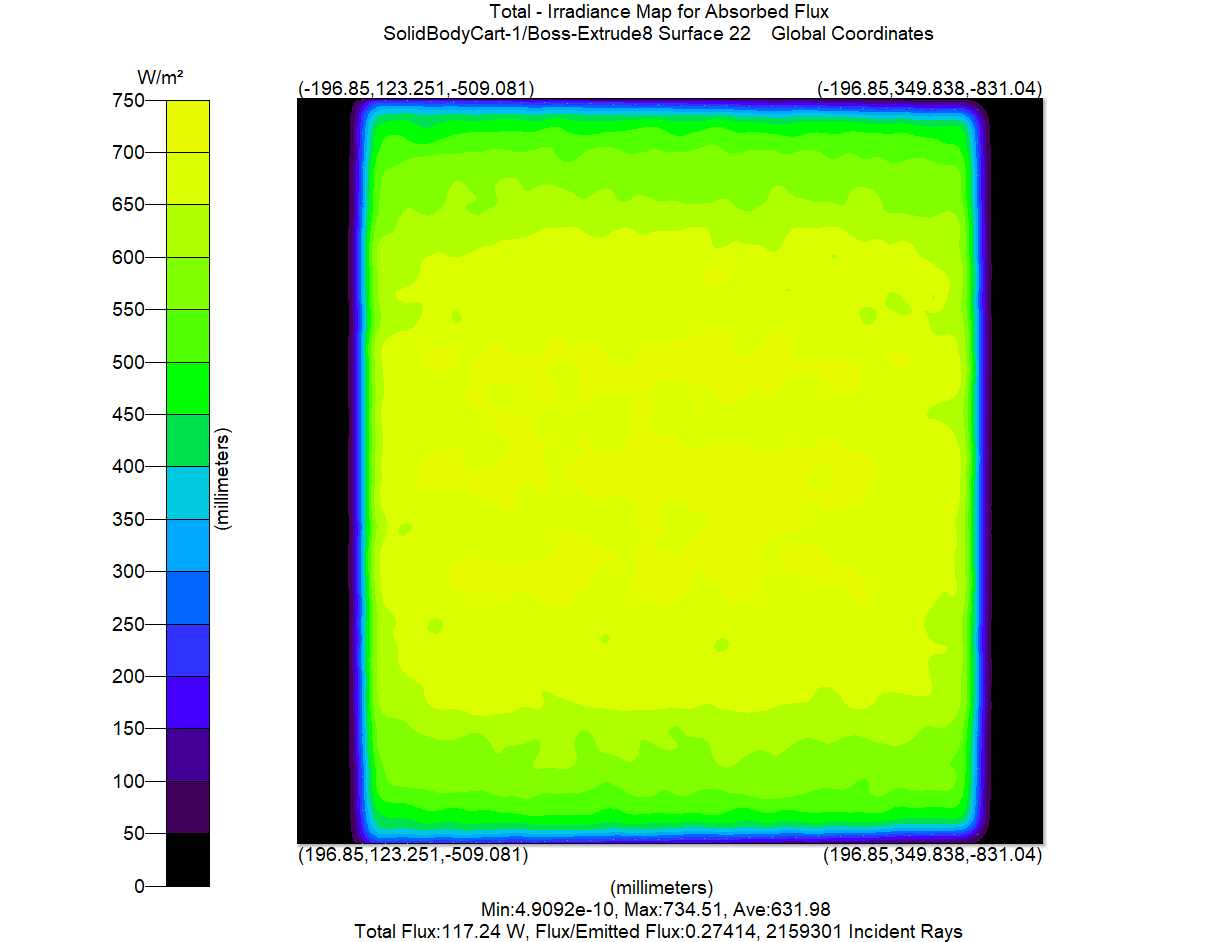

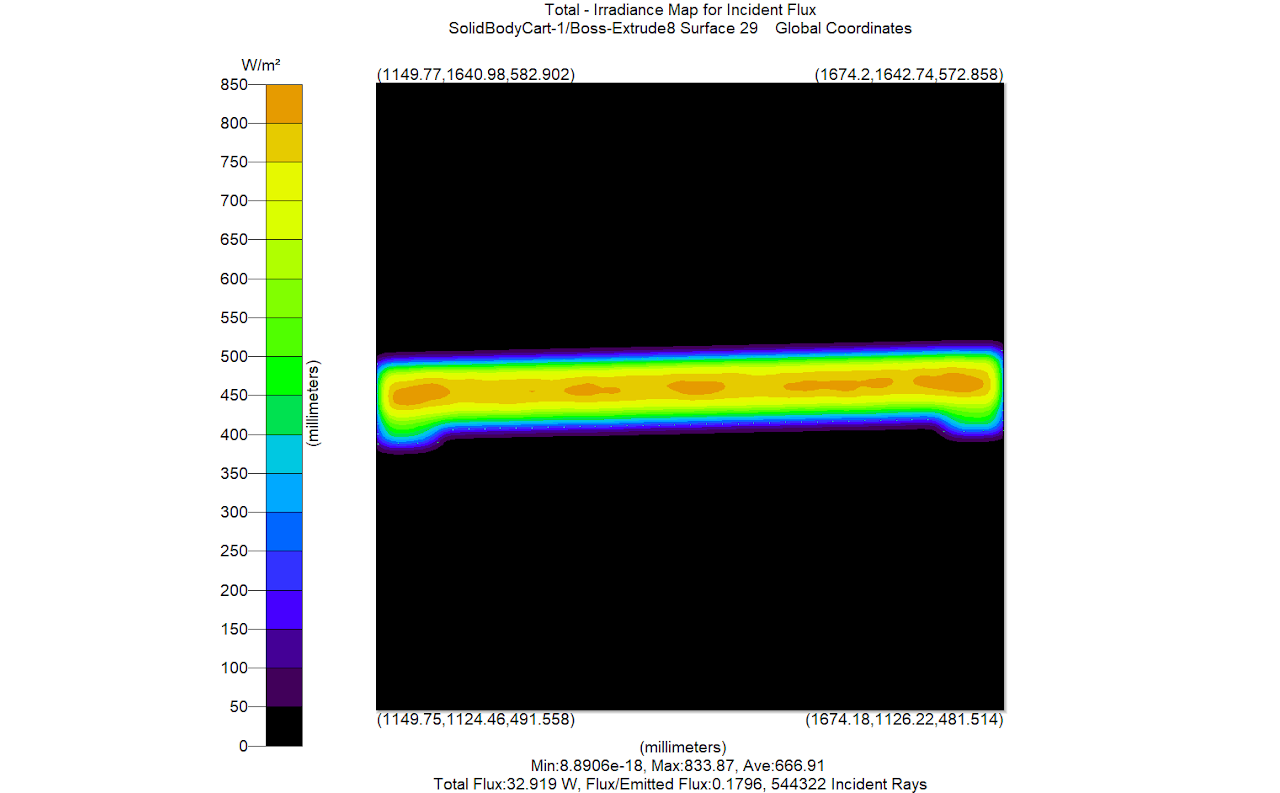

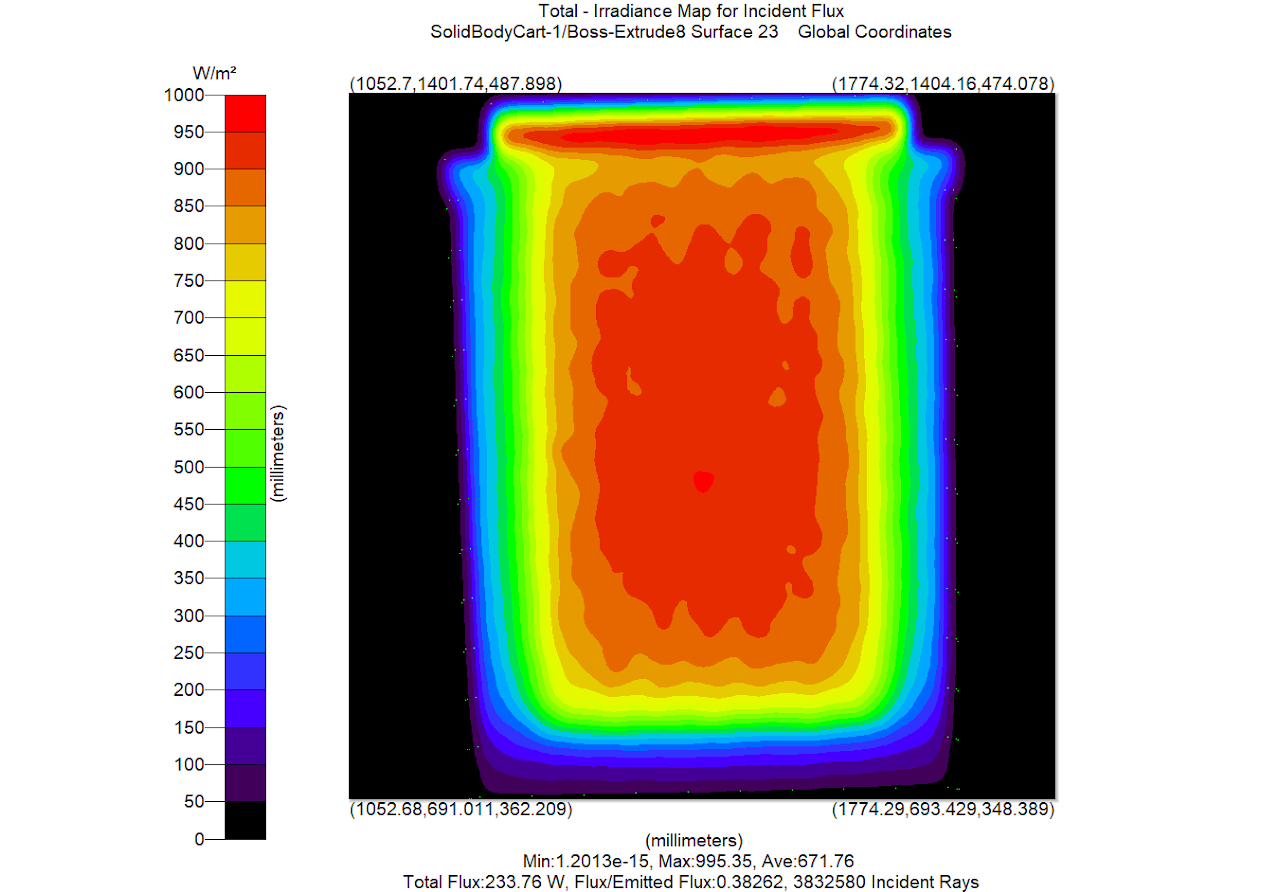

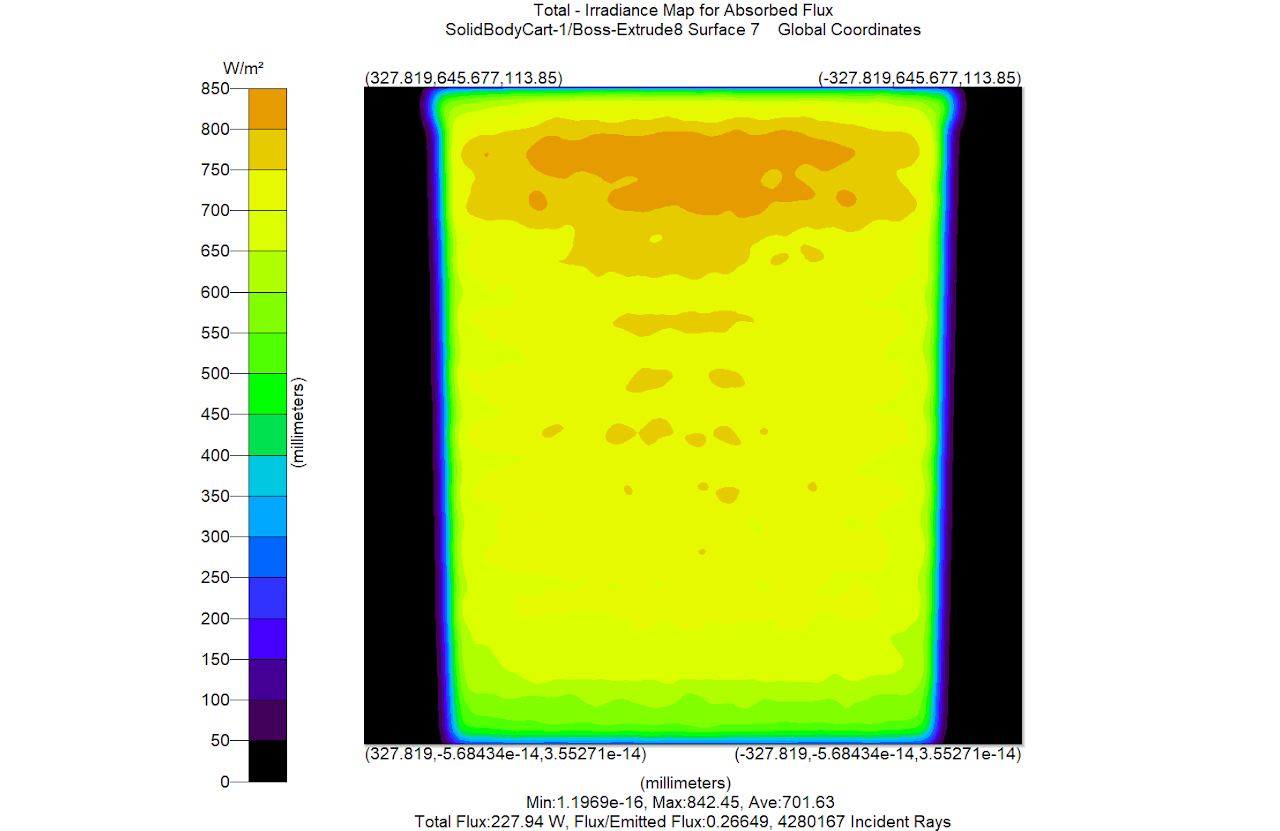

In order to simulate the behavior of UV rays in the sterilization machine, I utilized advanced ray tracing techniques to simulate rays o the magnitude of 10e6 (millions) per simulation. By modeling the 3-Dimensional geometry of the fixtures, incorporating the properties of UV light and the material properties of the shopping cart. The simulation accurately predicts the distribution of UV dosage throughout target areas. This simulation played a crucial role in optimizing the fixture's design and ensuring the goal for a log3 reduction of RNA viruses was met.

Simulation Results

These simulation results reveal promising results in terms of reaching the removal of pathogens such as COVID-19 from the cart surface.

Image Processing

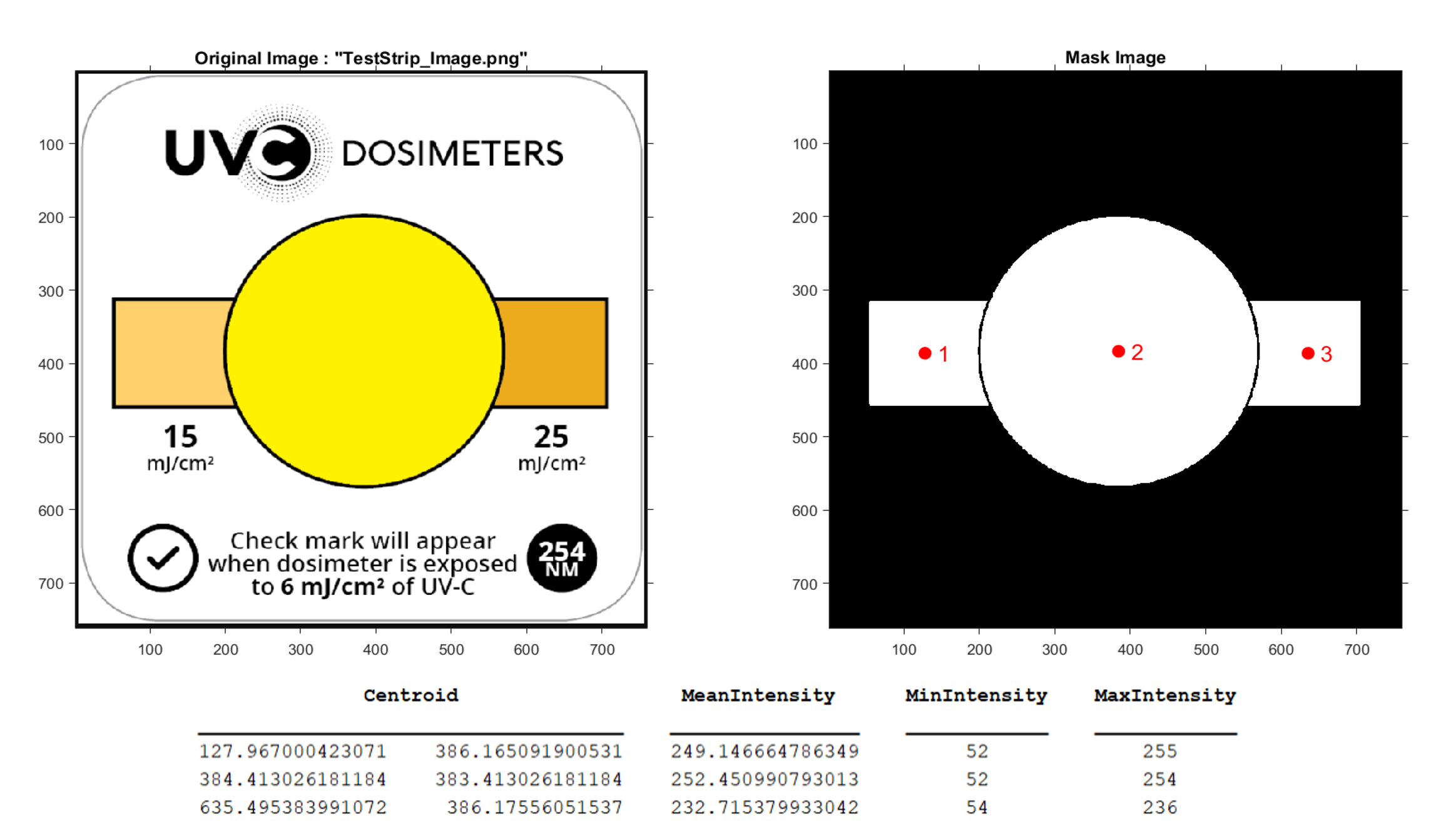

The image processing component of this project involved developing algorithms to analyze the captured images and extract relevant information about the UV dosage distribution. By applying image processing techniques such as edge detection, thresholding, and contour analysis, I was able to quantify the effectiveness of the UV sterilization process. This analysis provided valuable insights into areas that required further optimization and helped validate the simulation results.

Image Processing

Image Processing Results

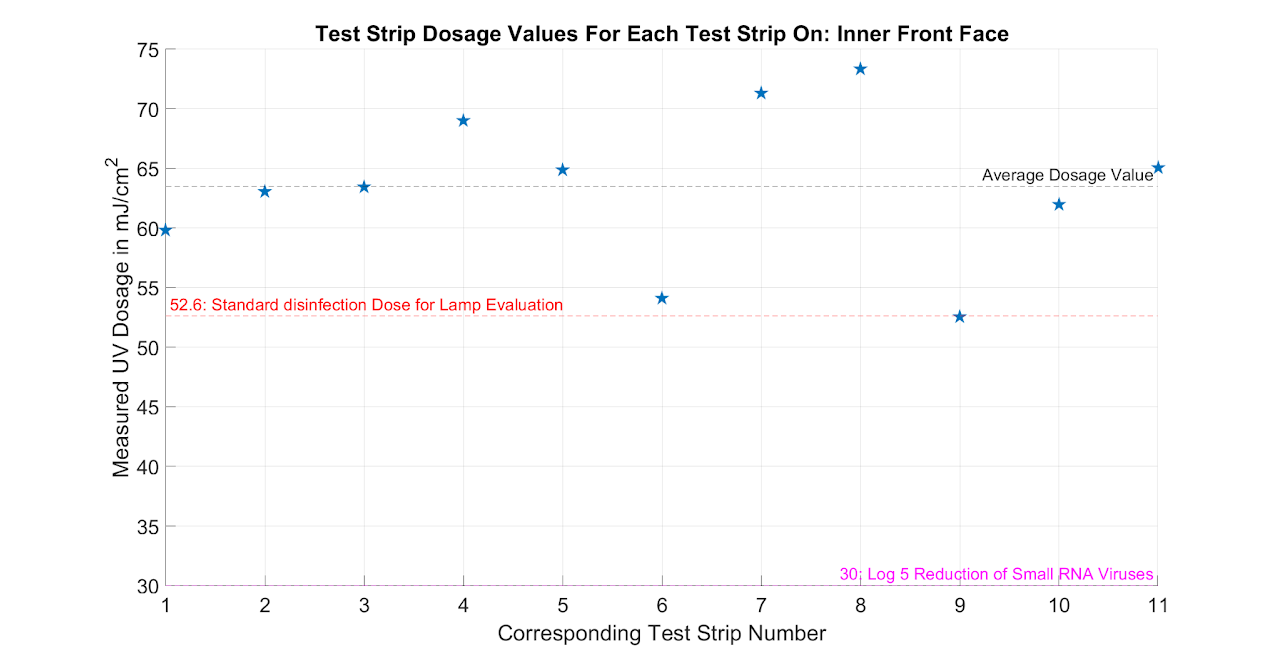

Front Face Inner

Front Face Inner

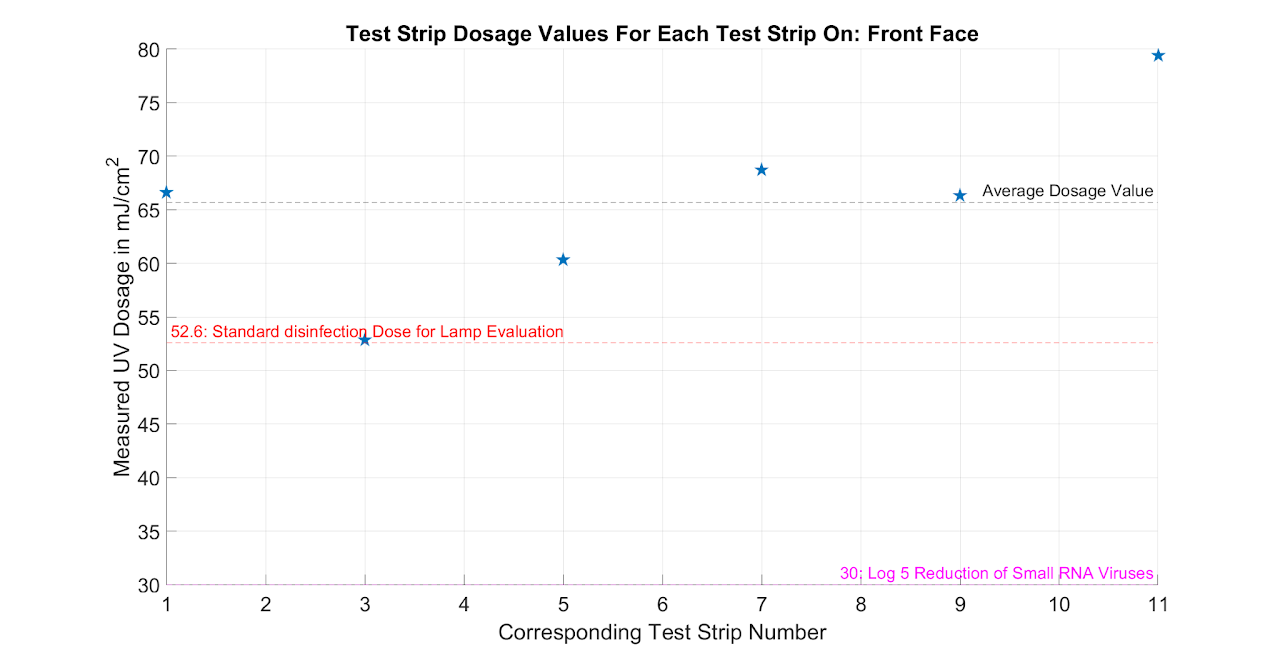

Front Face

Front Face

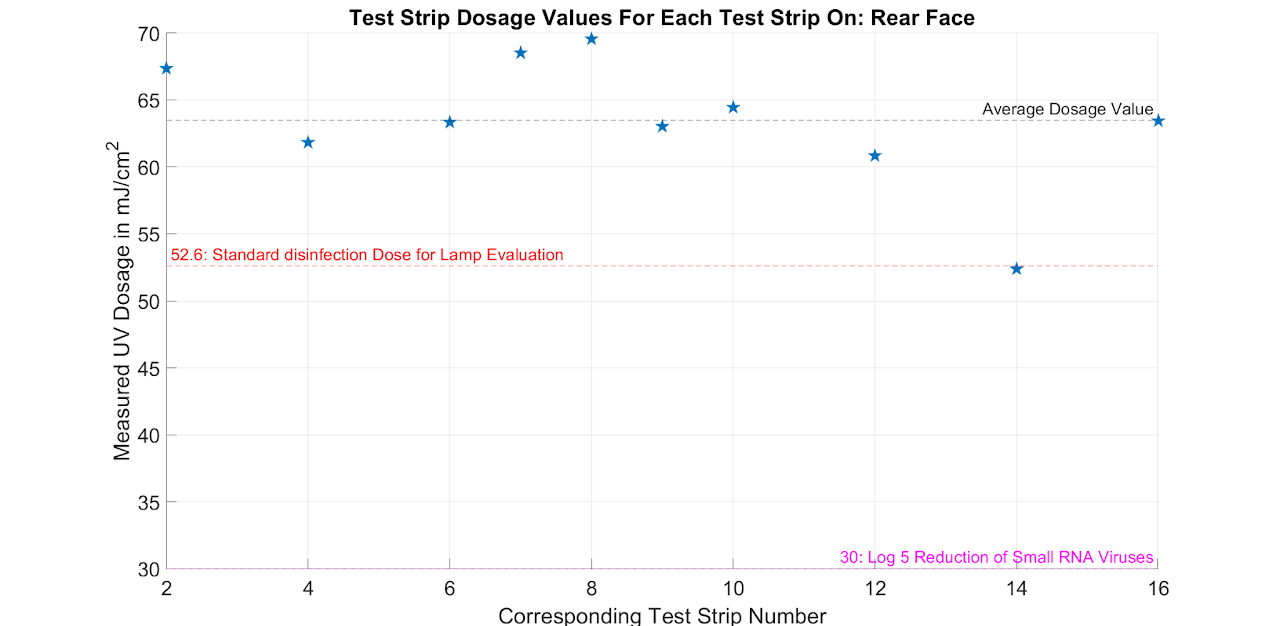

Rear Face

Rear Face

The expiremental results valiadte the simulation and demonstrate a strong promise of acheiving log 3 reduction of pathogens from the cart surface.

Acknowledgments

Extension of gratitude to Jeffrey Levitt and Applied UVc for sponsoring this project and providing the necessary resources and support to make it a success. I would also like to thank everyone on the team involved (Alphabetical by Last Name): Nethmi Arachchi, Liam Carmody, Adam Douglas, Aryian Schreiner. More information on the project can be found here.